One Component Polyurethane Waterproof Coating (DmcCoat 1401)

One Component Polyurethane Water-proof Coating (Type I)

DmcCoat 1401

1. Product Description

One-component polyurethane waterproof coating is an environmentally friendly reactive polymer waterproof coating. It is evenly coated on the construction base surface with scrapers, rollers and other tools. It can react with moisture and consolidate to become elastic, strong and durable waterproof coating.

2. Technical Specifications

|

Product Name |

One Component Water-proof Coating |

|

| Type |

Polyurethane Series |

|

| Main Components |

Polyurethane Prepolymers, environmentally friendly solvent |

|

| Standard |

GB/T 19250-2013 |

|

| Application Areas | Permanent waterproofing of roofs, walls, basements, pools, and toilets | |

| Appearance |

Black liquid |

|

| Viscosity(23℃) |

6000-8000mPa·S |

|

| Construction Time |

60 min |

|

| Tack-free Time(23℃) |

5.5-8h |

|

| Solid Content |

90% |

|

|

Performances Comparison |

Tensile Strength |

≥2MPa |

| Elongation at Break |

550-1000% |

|

| Tear Strength |

17N/mm² |

|

| Strength retention rate after acid treatment |

>80% |

|

| Strength retention rate after alkali treatment |

>80% |

|

| Strength retention rate after heat treatment |

>100% |

|

| Elongation after acid treatment |

550% |

|

| Elongation after alkali treatment |

550% |

|

| Elongation after heat treatment |

550% |

|

|

Construction condition requirements |

1. Avoid construction below 5℃;

2. There is no water on the construction base surface; 3. The grassroots must be cleaned in advance to remove scum and dust; 4. The waterproof layer can be constructed after the concrete construction is completed for more than 2-3 weeks. |

|

|

Tools needed for construction |

Scraper, roller |

|

|

Construction protective equipment |

Safety helmets, gloves, protective glasses, protective masks |

|

|

Construction dosage |

Coating thickness 1mm, theoretical dosage is about 1.3kg |

|

3. Product Features

l High strength, high elongation and good elasticity;

l Dense film, no bubbles, no pinholes;

l No benzene solvents, no coal tar ingredients, no pollution to the environment and human body;

l Liquid, cold construction, flexible and convenient construction method;

l Strong bonding force (>1.5MPa), high performance long-term retention rate;

l Chemical reaction film formation, water resistance, corrosion resistance, mildew resistance, cold resistance, and strong water impermeability.

- Scope of application

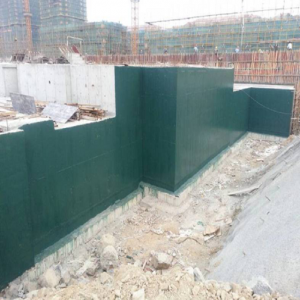

l Applicable to basement, toilet and kitchen;

l Waterproof and moisture-proof of pool, cold storage, floor and other projects;

l Applicable to underground engineering;

l It can also be used for waterproofing of non-exposed roofing projects.

5. Waterproof structure requirements

l Basic system composition: It should include waterproof base layer, additional waterproof layer, coated waterproof layer, closing head and edge closure, and protective isolation layer. In addition, the relevant levels should be set up scientifically and reasonably according to the function of the building.

l The internal and external corners should be made into arc shape, and the diameter of the internal corner should be greater than 50mm, and the diameter of the external corner should be greater than 10mm.

l Film waterproof layer: generally, it is a separate film waterproof structure, and an additional layer of matrix reinforcement material can be paved on the bottom plate of underground works.

l Coating film thickness: Underground engineering, it can be 1.2~2.0mm, recommended not to be less than 1.5mm, toilet and bath room should be no less than 1.5mm, when there are multiple fortifications in non-exposed roofing works, the thickness of each should not be less than 1.5mm, (according to the fortification The number of lanes is superimposed). When the waterproof level is Ⅲ roof fortification, the thickness of the waterproof layer should not be less than 2mm. When the carcass reinforcement is interposed between the coatings, the coating under the carcass should be less than 1mm, and the coating on the top should not be less than 0.5mm.

6. Construction Points

l Basic treatment and construction preparation: The base should be level, clean, firm and solid, without water, no sharp corners, no obvious wet stains, and the joint arc treatment should be done; ensure that the construction tools must be dry and clean.

l Detailed node additional layer:For the basic details such as the yin and yang corners, pipe roots, and deformation joints, additional waterproof layer construction should be carried out first, and additional coatings can be applied 2-4 times (thickness not less than 1mm).

l Large surface waterproof layer coating: Coat the mixture uniformly with a rubber or plastic scraper, requiring uniform thickness. Generally, it is about 1.5mm, divided into 2-3 coats, and the next painting should be done in different directions after the previous painting is cured to form a film.

l Close-up and edge treatment: Add paint for key sealing.

l Protective isolation layer: The surface of the coating waterproof layer should be constructed as a protective isolation layer according to the design requirements.

7.Attentions

l There should be no clear water on the base of the project, otherwise the construction should be done after draining for 24 hours;

l It is advisable to construct at a temperature above 5℃, and the construction site should be well ventilated and fire-fighting equipment should be placed;

l After opening the barrel, it should be used up as soon as possible, and the time should not exceed 60 minutes; avoid direct exposure to the air for a long time to prevent skin formation. The unused material after opening the lid should be tightly closed immediately, and the remaining material shall be used up as soon as possible;

l Before the coating film is dry, it is strictly prohibited to walk on the waterproof layer, and pay attention to protect the construction site.

8. Packaging, storage and transportation

l The product is stored in a clean, dry and airtight iron bucket;

l According to the requirements of dangerous goods, prevent rain, exposure, squeezing, and collision, and ensure that the packaging is intact;

l The product should be stored in a ventilated, dry, and cool place to prevent direct sunlight and rain. The storage temperature should not be higher than 40℃;

Under normal storage conditions, the shelf life is 6 months.